Call us

+86-18023576732

+86-0579-89008006

Fax: +86-0579-82206899

When evaluating how to enhance the cooling performance of a Brushless Motor Barrier Gate, it is essential to recognize the types of heat generated within the system. Brushless motors eliminate frictional heat from brushes, yet they still produce significant thermal loads due to continuous duty cycles, high torque demands, and confined installation environments. The control board, power electronics, and gearbox also contribute to temperature rise, especially during peak traffic periods. If the internal temperature exceeds safe limits, users may experience torque reduction, slower response time, or premature failure of electronic components. Therefore, improving thermal management is not only a matter of longevity but also a necessity for stable and reliable gate operation.

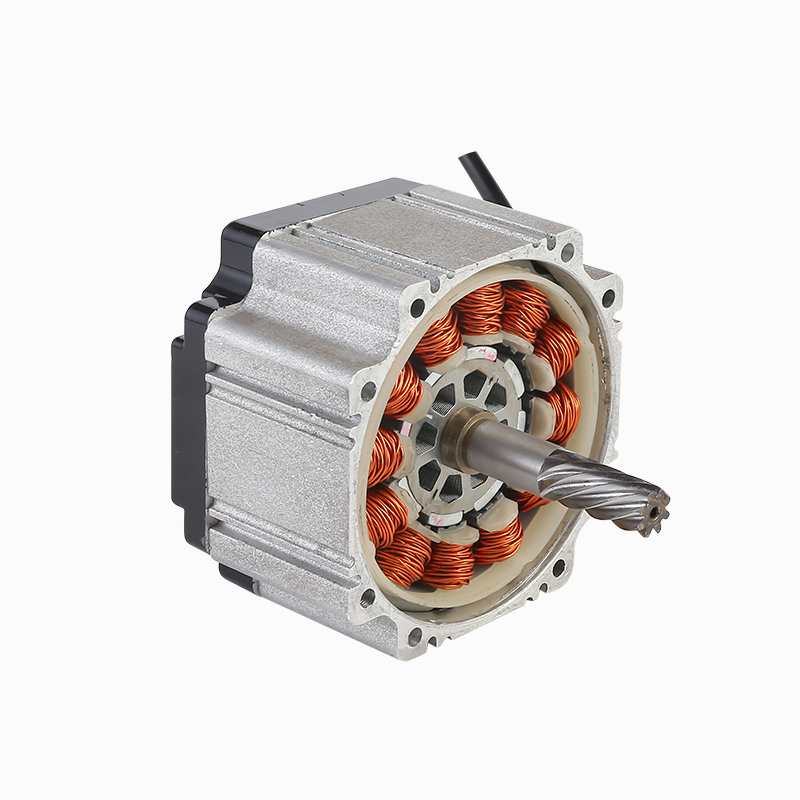

One of the effective ways to improve cooling is to refine the structural design of the motor and its surrounding housing. Increasing surface area through finned aluminum housings accelerates conductive and convective heat dissipation. Selecting motor shells made from high-thermal-conductivity materials ensures that internal heat moves outward quickly rather than accumulating near sensitive windings. Internally, using high-grade copper windings and precision stator laminations reduces electrical losses that would otherwise convert into unnecessary heat. Designers may incorporate ventilation channels within the gate body, guiding airflow from cooler external areas toward the motor enclosure to accelerate heat transfer.

Airflow is the backbone of effective cooling, and even small adjustments can generate significant improvements. Installing strategic air inlets and outlets ensures a continuous path for heat to escape. Some barrier gate systems integrate compact cooling fans to create forced airflow across the motor, driver board, and gearbox. These fans may be activated only during peak thermal periods through temperature sensors, preventing unnecessary energy consumption. In outdoor barrier systems where environmental contaminants may pose risks, dust-resistant or waterproof fans are preferred to maintain reliability. Implementing forced convection dramatically lowers internal temperatures compared to natural air circulation alone.

Another powerful method of improving cooling efficiency is the use of thermal interface materials (TIMs) and heat spreaders. TIMs fill microscopic gaps between heat-generating components and their cooling surfaces, reducing thermal resistance and enabling smoother heat flow. Heat spreaders made from copper or graphite effectively redistribute localized hotspots across larger surfaces of the housing. When applied to motor drivers or MOSFET modules, these materials significantly reduce the risk of thermal cycling damage. Combined with a well-designed heatsink, TIMs create a stable thermal environment even during continuous, high-frequency gate operation.

Although the motor is the primary heat source, the gearbox contributes a surprising amount of thermal energy when lubrication is insufficient or mechanical load is high. Using high-performance synthetic lubricants reduces friction, lowers internal temperature, and ensures smoother motion. Reducing mechanical drag through precision machining, tighter tolerances, and high-quality bearings also helps reduce unnecessary heat. By reducing friction-related energy loss, the entire system becomes thermally efficient and easier to cool.

Improving the cooling performance of a Brushless Motor Barrier Gate requires a multi-layered approach that combines structural design, airflow management, lubrication improvements, and intelligent thermal monitoring. When these elements work together, the barrier gate achieves stable operation, reduced thermal stress, and extended service life even in demanding outdoor environments. By viewing cooling as a system-wide challenge rather than a single-component issue, engineers can create more durable, reliable, and efficient barrier gate solutions.

Contact Us