Call us

+86-18023576732

+86-0579-89008006

Fax: +86-0579-82206899

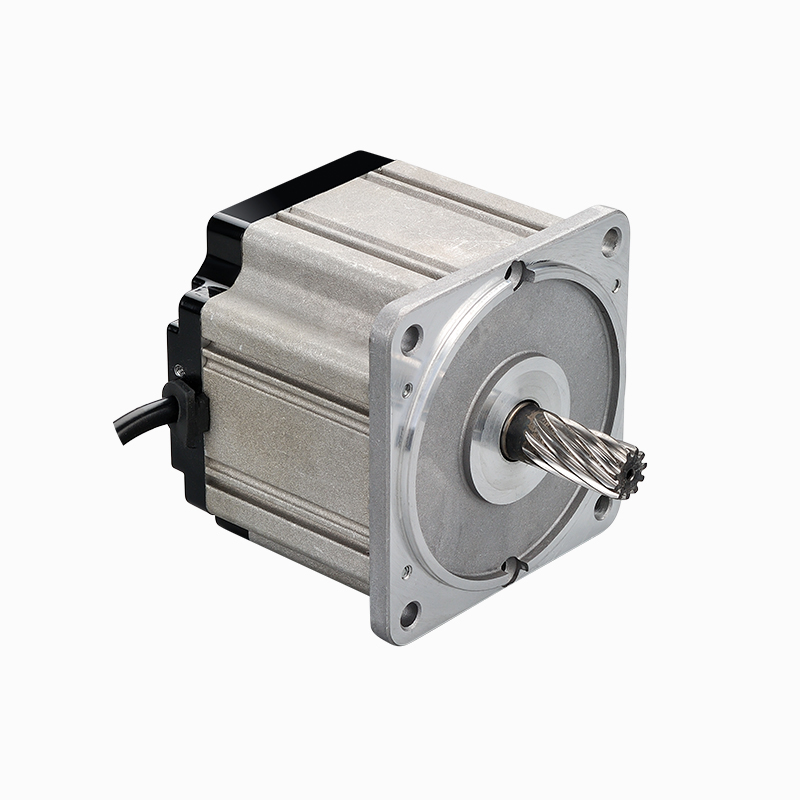

The Brushless Motor Barrier Gate is a widely used solution for controlling vehicle access in parking lots, commercial areas, and residential complexes. One of the critical components that determines its performance is the gear reduction mechanism. This system converts the high-speed, low-torque output of the brushless motor into low-speed, high-torque motion suitable for lifting and lowering the barrier arm. Understanding how the gear reduction affects motor performance is essential for designing reliable and efficient barrier systems.

A primary function of the gear reduction mechanism is to increase torque. Brushless motors typically operate at high rotational speeds with limited torque. Without a gear reduction system, the motor would struggle to lift a barrier arm efficiently, especially under heavy loads or in windy conditions. By employing a gearbox with an appropriate reduction ratio, the motor’s torque is multiplied, providing sufficient force to move the barrier smoothly and reliably. This allows the barrier gate to operate consistently even under high resistance conditions.

While increasing torque, gear reduction also decreases the output speed of the barrier arm. This slowdown is beneficial because it allows precise and controlled movement. Smooth acceleration and deceleration are critical for safety, preventing sudden jerks that could damage the barrier mechanism or endanger nearby individuals. Additionally, slower movement reduces the impact on the motor, reducing wear and tear over time. The gear reduction mechanism ensures that the barrier gate opens and closes at a suitable speed for both performance and safety.

The gear reduction system also affects the overall efficiency of the Brushless Motor Barrier Gate. By enabling the motor to operate within its suitable speed and torque range, the gearbox reduces the likelihood of overloading or overheating. A properly matched reduction ratio ensures that the motor does not need to exert excessive force, which can prolong its lifespan and reduce energy consumption. However, inefficient gear design or improper reduction ratios can introduce frictional losses, slightly lowering overall system efficiency. Therefore, high-quality gears and accurate ratios are essential for reliable operation.

A well-designed gear reduction mechanism not only improves torque and control but also contributes to the longevity of the motor. By decreasing the load stress on the motor, the gearbox reduces mechanical strain and heat generation, reducing the frequency of maintenance. Lubrication of the gear teeth and regular inspection of the gearbox are important to maintain consistent performance. Neglecting these aspects can cause premature wear, increased noise, and potential failure of the barrier gate system.

When selecting a gear reduction system for a brushless motor barrier gate, engineers must consider the barrier arm weight, desired open and close speeds, and expected operational frequency. Matching the motor characteristics with the gearbox ensures that the barrier operates smoothly, safely, and efficiently. Manufacturers often provide specifications that recommend suitable gear ratios based on motor output and load requirements.

The gear reduction mechanism is a fundamental component that significantly influences the performance of a Brushless Motor Barrier Gate. It amplifies torque, controls movement speed, enhances efficiency, and reduces motor stress, ensuring smooth and reliable operation of the barrier arm. Selecting the correct reduction ratio and maintaining the gearbox are essential for improving the lifespan and safety of the barrier system. Understanding the interaction between the motor and the gear reduction mechanism allows for better design, more efficient operation, and improved overall performance in access control applications.

Contact Us