Call us

+86-18023576732

+86-0579-89008006

Fax: +86-0579-82206899

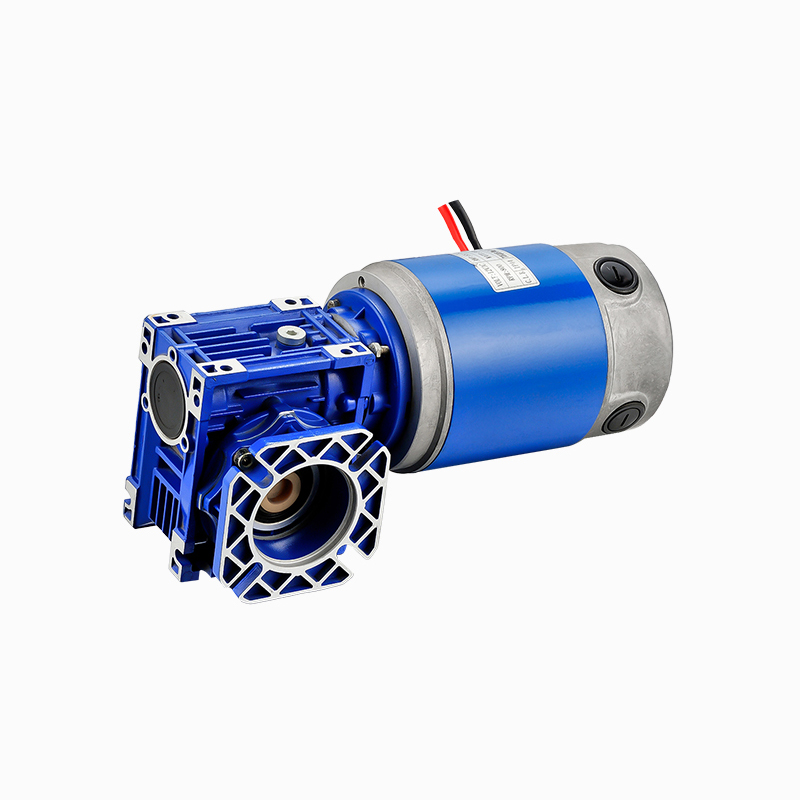

When evaluating the durability and reliability of motors used in industrial devices, automotive systems, or consumer equipment, the question of whether a DC brushed motor overheats during high-load operation becomes essential. Manufacturers, including specialized DC Brushed Motor Factory groups, continuously optimize design elements to improve thermal stability. Because brushed motors rely on physical contact between brushes and commutators, heat generation is a natural part of their working process. The challenge lies in managing this heat effectively to maintain performance and extend operational life.

During high-load operation, the electrical current increases to supply enough torque. Higher current results in greater resistive heating in the windings, brush-commutator friction, and electromagnetic losses. Under these conditions, a DC brushed motor experiences elevated internal temperatures, especially if it runs continuously near peak torque levels. Without proper cooling paths or thermal design, accumulated heat can degrade insulation, reduce magnetic efficiency, and accelerate wear on brushes and bearings. Therefore, overheating risk is directly tied to mechanical stress, current flow, and duty cycle.

The brush-commutator interface is one of the primary heat sources in a brushed motor. Each contact point produces friction and sparks, both of which are intensified during heavy loading. Heat produced at this interface can spread through the rotor assembly, adding to thermal stress. Over time, excessive heat may harden or damage brushes, increase electrical resistance, and cause commutator pitting. To decrease these effects, DC Brushed Motor Factory designers typically optimize brush material and spring pressure to balance conductivity and friction, limiting unnecessary heat buildup.

The degree to which a brushed motor overheats under load depends on its design. Larger motors often manage heat better due to thicker windings, larger air gaps, and more robust housing structures. Motors with higher-grade copper windings and efficient lamination stacks reduce losses and resist thermal saturation. Additionally, well-engineered airflow channels, metal casings, and optional external cooling components contribute to heat dissipation. In contrast, compact motors with minimal ventilation are more prone to overheating when driven under heavy loads for extended periods.

External conditions can amplify heating challenges. Poor ventilation, elevated ambient temperatures, and dust accumulation can restrict air movement and thermal transfer. High humidity may also affect lubrication and brush wear, indirectly contributing to heat buildup. If the motor operates within a sealed enclosure or near heat-generating components, internal temperatures can escalate rapidly. To counter these risks, operators must ensure proper installation spacing, ventilation, and periodic cleaning to maintain cooling performance.

Proper control and safety systems are critical to protecting motors from overheating. Current-limiting circuits, thermal overload protection, and soft-start controllers help moderate operating stress. Pulse-width modulation speed control can distribute thermal load more evenly, especially in applications requiring variable torque. High-end units may include heat sensors or automatic thermal shutoff features. Many DC Brushed Motor Factory manufacturers recommend pairing motors with load-matching gear systems to reduce torque stress during operation.

Routine maintenance significantly reduces overheating risk. Brush inspection and replacement prevent carbon buildup that increases resistance and heat. Ensuring proper lubrication reduces bearing friction. Motor housings and cooling vents should remain clean and unobstructed. When wear indicators appear, such as reduced torque, burn odor, discoloration, or audible brush noise, timely maintenance helps prevent irreversible damage.

A DC brushed motor can overheat under high-load conditions, especially with prolonged operation, inadequate cooling, or poor maintenance. However, with optimized motor design, prudent load management, effective ventilation, and regular upkeep, overheating risk can be significantly reduced. By selecting the right motor specifications and applying proper operating practices, users can ensure stable performance and extend the lifespan of brushed motors in demanding environments.

Contact Us