Call us

+86-18023576732

+86-0579-89008006

Fax: +86-0579-82206899

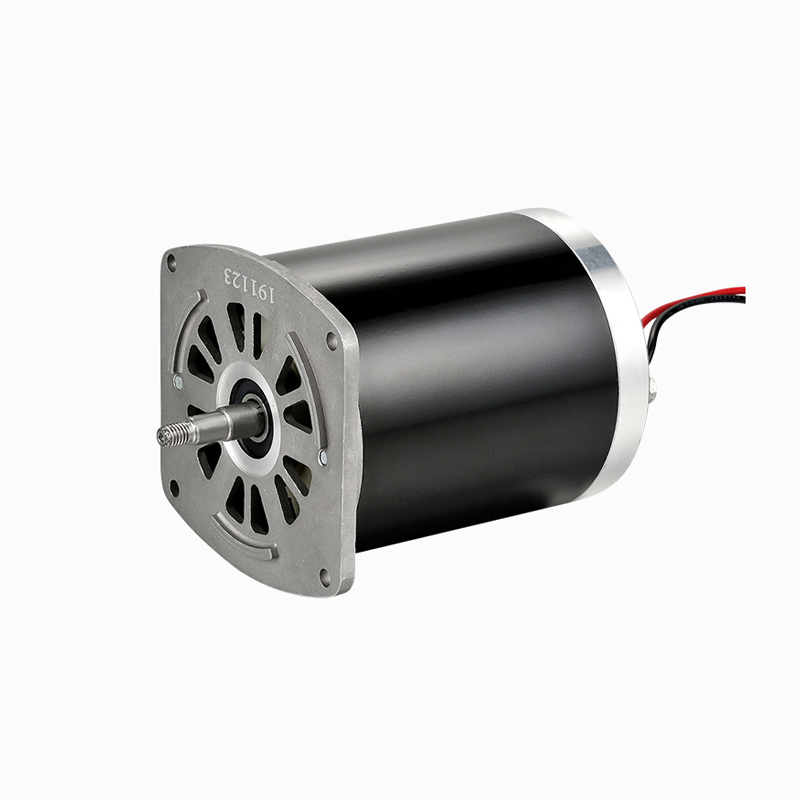

The efficiency of electric motors is a critical factor that determines energy consumption, operational cost, and overall system performance. Among various types of motors, the Permanent Magnet DC Motor is widely recognized for its compact size, high torque-to-weight ratio, and ease of speed control. However, like all electric machines, its efficiency is not constant and varies significantly with load conditions. Understanding this variation is essential for engineers and designers aiming to optimize performance and prolong motor lifespan.

Efficiency at Low Load Conditions

When a motor operates under light load or no-load conditions, efficiency is generally lower compared to its performance at rated load. This is primarily due to fixed losses such as friction, windage, and core losses, which do not decrease proportionally with reduced mechanical output. In the case of a Permanent Magnet DC Motor, the energy required to overcome internal friction and magnetic hysteresis remains relatively constant, meaning that at light loads, the proportion of energy lost is higher. As a result, motors running consistently under light loads may appear less efficient despite consuming minimal absolute power.

Performance at Rated Load

Motors typically achieve peak efficiency when operating near their rated load. At this point, the balance between electrical and mechanical losses is good, allowing the machine to convert a higher percentage of input electrical energy into useful mechanical work. For a Permanent Magnet DC Motor, the interaction between the rotor's magnetic field and the stator current is effective at this operating point. Engineers often design motor-driven systems to operate close to rated load to take advantage of this suitable efficiency, especially in applications where energy savings are a priority, such as electric vehicles or automated machinery.

Behavior Under Overload Conditions

When subjected to overload conditions, motor efficiency can decrease significantly. Higher loads increase current flow through the motor windings, causing elevated copper losses due to resistive heating. Additionally, the excessive current can cause the motor to heat up, which in turn increases core losses and may affect the magnets’ performance over time. Although Permanent Magnet DC Motors can handle short-term overloads, sustained operation beyond rated capacity is not recommended, as it can cause reduced efficiency, overheating, and potential permanent damage. Proper thermal management and protective circuitry are crucial to mitigate these risks.

Impacts of Variable Load Applications

In real-world applications, motors often operate under variable loads, where the torque and speed requirements fluctuate dynamically. Efficiency in such scenarios depends on both load magnitude and duty cycle. Advanced control strategies, such as pulse-width modulation and torque control, can help maintain higher efficiency across varying conditions. Additionally, selecting a motor with an efficiency curve that aligns with the expected load profile ensures that energy consumption remains suitable throughout operation. Monitoring systems can provide feedback to adjust motor parameters dynamically, further improving performance.

Efficiency variations in motors are an inherent consequence of load-dependent losses. The Permanent Magnet DC Motor demonstrates high efficiency near its rated load, while efficiency drops at low or excessive loads due to fixed and resistive losses. By carefully matching motor specifications to application requirements and employing intelligent control strategies, designers can improve energy efficiency, reduce operational costs, and extend the lifespan of the motor. Understanding these principles is key to leveraging the full potential of motor-driven systems in diverse industrial and commercial applications.

Contact Us